Key Parameters and Storage Concerns

Used cooking oil is a valuable resource for biodiesel production and other applications. However, its quality can degrade significantly over time, especially when stored improperly. Understanding the factors that contribute to this degradation is crucial for maintaining the oil’s efficacy and safety. This blog explores how parameters like Free Fatty Acids (FFA) and water content change as used cooking oil deteriorates in storage, particularly when kept in jerrycans.

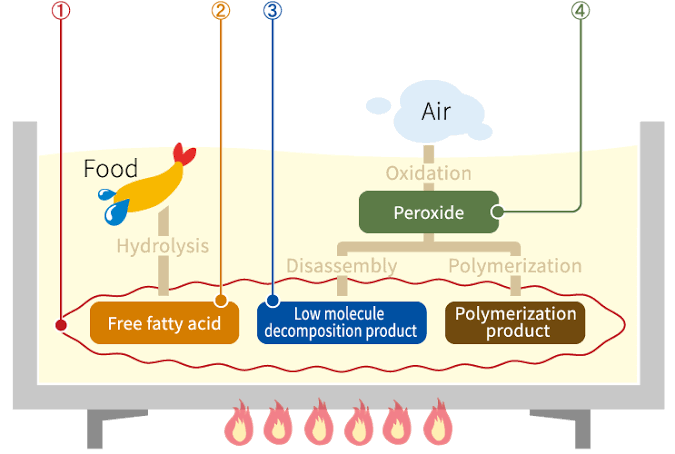

Understanding Oil Degradation

1. Free Fatty Acids (FFA)

Free Fatty Acids are a primary indicator of oil quality. They form when triglycerides in the oil break down into fatty acids and glycerol due to oxidation and hydrolysis. Over time, as used cooking oil is exposed to air, light, and heat, the FFA levels increase. High FFA levels can affect the oil’s usability in biodiesel production, making it less efficient and more corrosive.

- Initial Stages: Freshly used cooking oil might have relatively low FFA levels.

- Long-Term Storage: Over time, the FFA content increases due to the breakdown of triglycerides. This rise is accelerated by factors like temperature, exposure to air, and light.

2. Water Content

Water Content is another critical parameter. Water can enter the oil through condensation or from food residues. Excessive water content can lead to microbial growth and accelerate the oil’s deterioration.

- Initial Stages: Immediately after use, the water content is relatively low but can increase due to moisture absorption.

- Long-Term Storage: Prolonged storage in jerrycans, especially if they are not sealed properly, can lead to significant water absorption. This additional moisture promotes oxidation and microbial activity, further degrading the oil.

3. Oxidation and Rancidity

Oxidation is a major factor in the degradation of used cooking oil. Exposure to air accelerates the oxidation process, leading to rancidity. Rancid oil has off-flavors and odors and is less suitable for biodiesel production.

- Initial Stages: The oil may still have a relatively neutral odor and taste.

- Long-Term Storage: Over time, oxidation leads to the formation of peroxides and aldehydes, causing the oil to smell and taste rancid. This process is exacerbated by light and high temperatures.

4. Acidity and Peroxide Value

Acidity and Peroxide Value are other important indicators of oil quality. As the oil degrades, its acidity increases, and peroxide values rise, indicating higher levels of oxidative degradation.

- Initial Stages: Both acidity and peroxide values are within acceptable ranges.

- Long-Term Storage: These values increase as oxidation progresses, making the oil less suitable for use.

Storage Tips to Minimize Degradation

- Seal Properly: Ensure that jerrycans are tightly sealed to minimize air exposure and moisture ingress.

- Store in a Cool, Dark Place: Keep the oil in a cool, dark environment to slow down oxidation and rancidity.

- Avoid Direct Sunlight: UV light accelerates the degradation process. Store containers away from light sources.

- Use Clean Containers: Make sure the jerrycans are clean and dry before filling them to avoid introducing contaminants and moisture.

- Regular Monitoring: Periodically check the oil’s FFA levels, water content, and other quality indicators to assess its condition.

Key Take Away

The quality of used cooking oil degrades over time due to factors such as increased Free Fatty Acids, higher water content, and oxidative rancidity. Proper storage practices can help mitigate these effects and extend the usability of the oil. By understanding these parameters and taking steps to minimize degradation, you can ensure that your used cooking oil remains a valuable resource for biodiesel production and other applications.